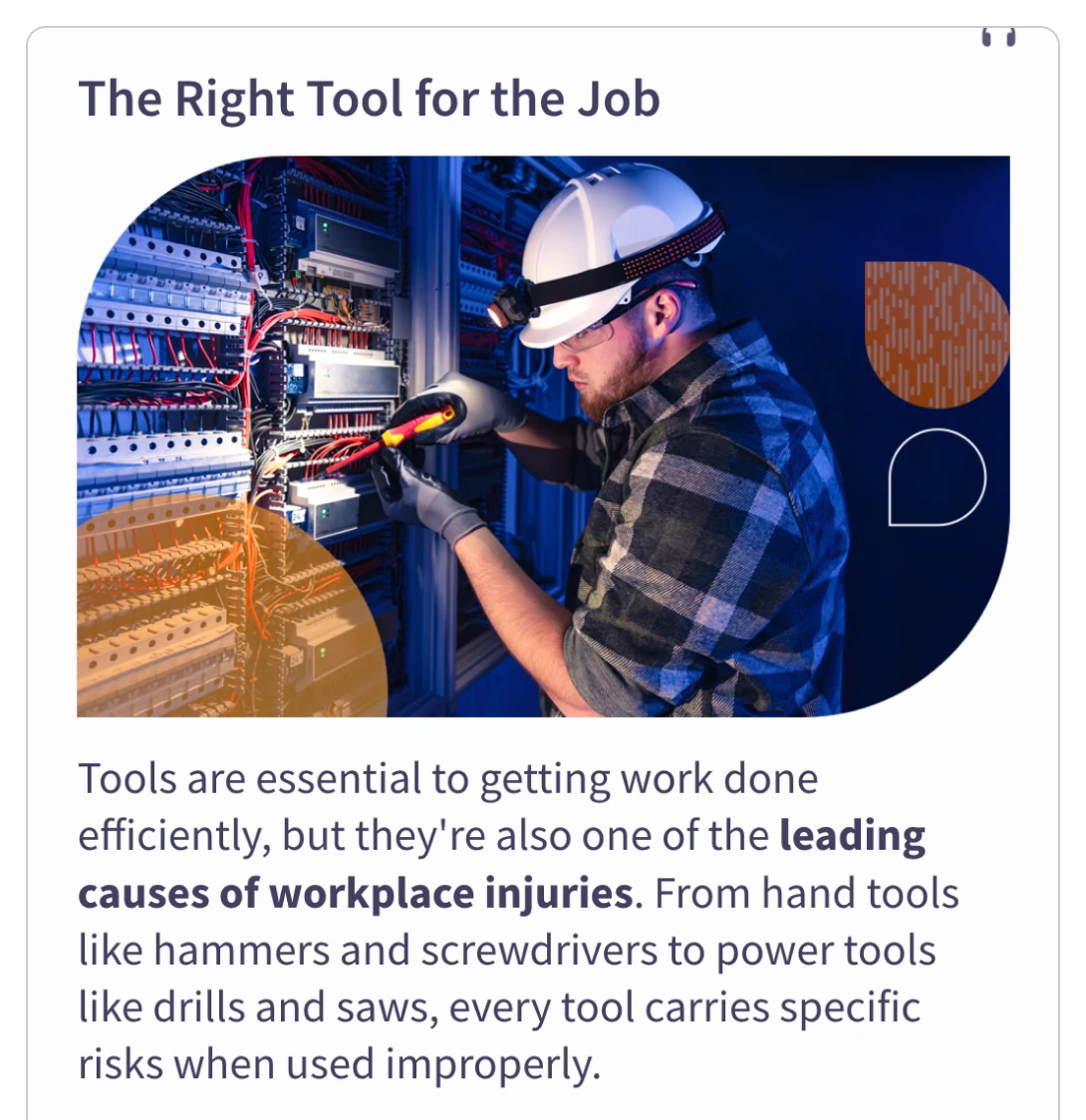

Preventing Injuries Before They Happen

Tools are essential to nearly every workplace, but they are also one of the most common sources of preventable injuries. From quick “one-minute” tasks to routine maintenance work, small oversights—like skipping a tool inspection or ignoring PPE—can lead to serious harm in seconds. Tool Safety focuses on building everyday habits that reduce risk, protect your body, and ensure everyone goes home safely at the end of the day.

Microlesson Description

The Tool Safety microlesson provides a practical framework for identifying hazards before they turn into injuries. Learners are guided through pre-use inspections, proper tool selection, safe operating practices, and the correct use of Personal Protective Equipment (PPE). The lesson reinforces that safety is a professional responsibility—whether using hand tools or power tools—and emphasizes the importance of reporting damaged equipment, near-misses, and unsafe conditions immediately to protect both individuals and coworkers.Key Concepts

- Inspect every tool before use—small defects can cause serious injuries

- Match the tool to the task to avoid slips, breakage, and loss of control

- Understand the unique hazards of hand tools versus power tools

- Use required PPE such as safety glasses, hearing protection, and proper footwear

- Follow manufacturer instructions and never disable guards or safety features

- Secure workpieces and maintain stable work environments

- Store, maintain, and tag damaged tools properly

- Report equipment defects, unsafe conditions, and near-misses without delay

Microlesson Features

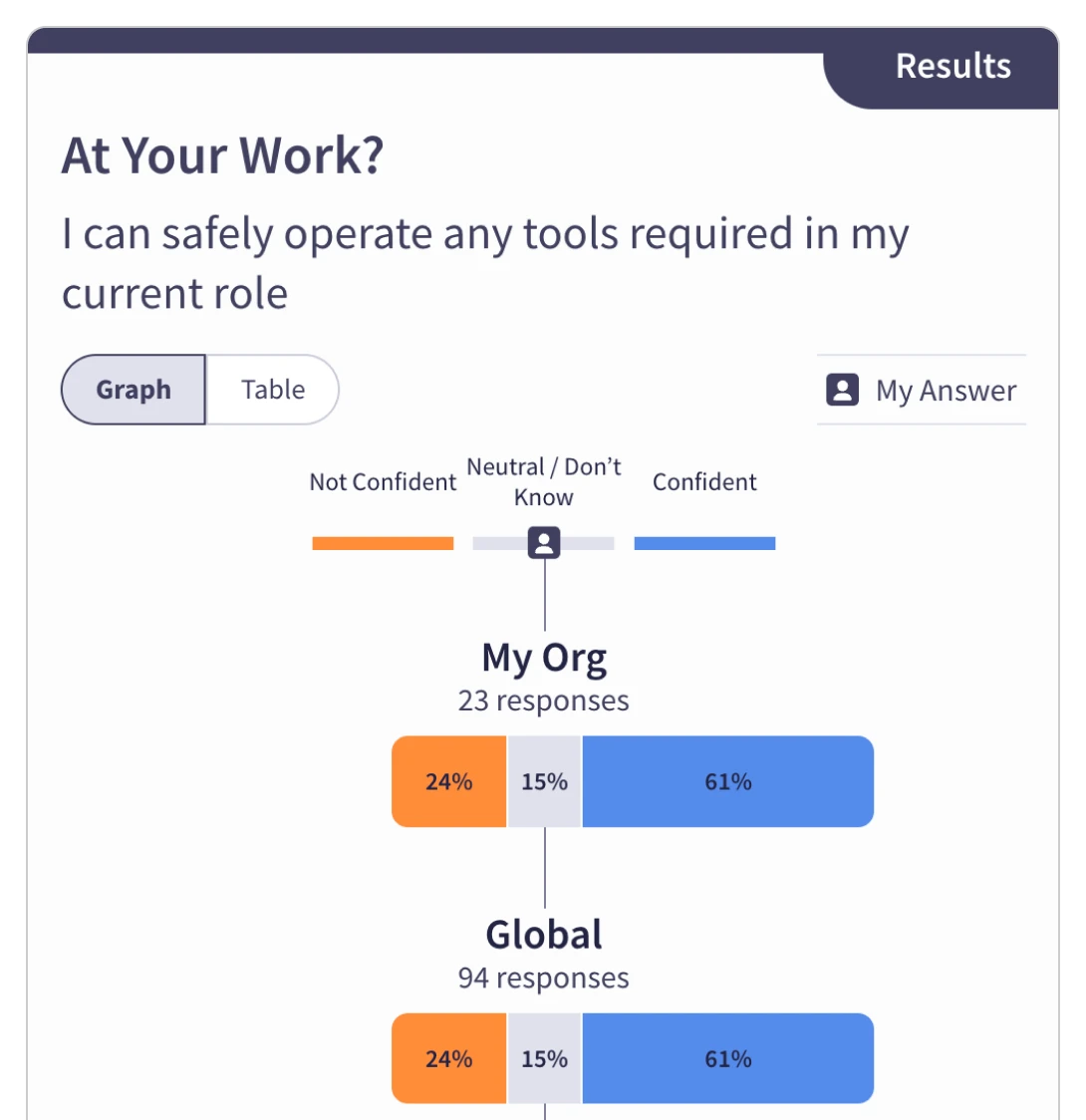

- Employee sentiment pulsing questions that provide leaders with insights into their workforce's core cultural competencies

- Emtrain's Expert Answers tool, enabling employeees to submit anonymous questions about sensitive issues.

- Rich, contemporary video scences illustrating key concepts through realistic scenarios

- A data driven, skill-based approach to eLearning that establishes a shared language for employees.

Related Resources

Related Trainings

Frequently Asked Questions

Below are answers to common questions that employees and managers have about this topic. These FAQs provide a preview of what you’ll learn in this microlesson and why it matters.

Q

Why are tool-related injuries so common in the workplace?

Tool injuries often occur during routine or quick tasks when people skip inspections, rush setup, or fail to wear PPE. These injuries are typically preventable with proper habits.

Q

What should I check during a pre-use tool inspection?

Inspect for cracks, loose parts, damaged handles, frayed cords, missing guards, dull cutting edges, and any signs the tool may not operate safely.

Q

Is it really necessary to inspect tools every time I use them?

Yes. Damage can occur between uses, and even a quick 30-second inspection can prevent serious injuries caused by hidden defects.

Q

What PPE is required when using tools?

At a minimum, safety glasses and appropriate footwear are required. Additional PPE—such as hearing protection, face shields, gloves, or respirators—may be necessary depending on the tool and task.

Q

Can I use a different tool if the correct one isn’t available?

No. Improvising with the wrong tool increases the risk of slips, breakage, and injury. Always use the tool designed for the specific task.